Modeling and analysis

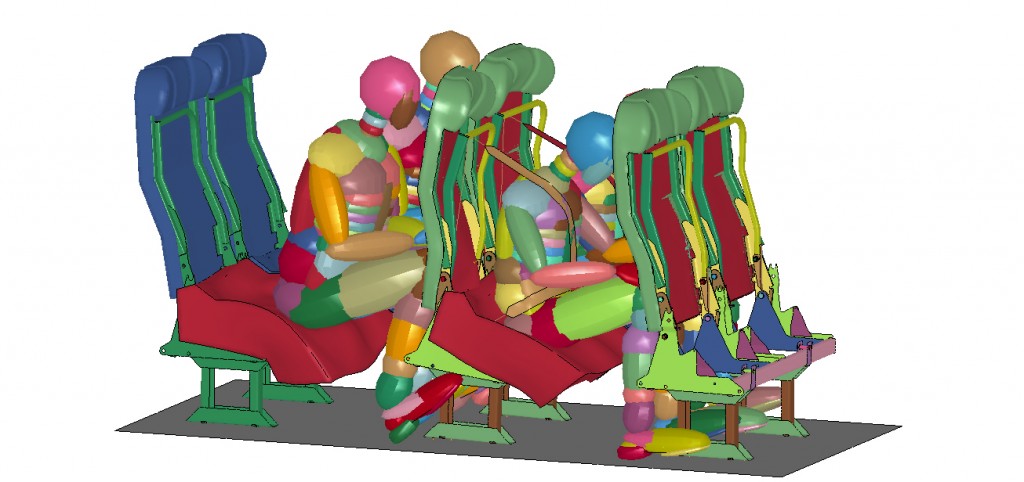

CAPE offers the services of engineering and technical personnel, including an applied mechanics engineering staff that provides modeling and analysis support, from vehicle crash analysis to component stress analysis. Applied mechanics analysis improves test efficiency and allows exploration of conditions beyond physical testing.

Once a model is created, multiple analyses can be conducted at a very low incremental cost. Design revisions or material substitutions can be incorporated into the model and then analyzed under similar conditions. This not only allows for direct comparison of analysis results, but it also enables engineers to analyze how a change affects other areas of interest.